CLEANING, FLUSHING AND FILLING OF NEW, MUDDY OR SILTED DISTRIBUTION NETWORKS

according to VDI 2030

We clean - flush and fill your heating and cooling networks for a trouble-free operation of your plant

The standard-compliant cleaning, flushing and filling of heating and cooling networks must be thoroughly planned and professionally executed as otherwise malfunctions and cost risks can occur within a short time.

Our experienced employees support tradesmen in all work related to the standard-compliant cleaning, flushing and filling of heating and cooling networks.

Our teams can be deployed at short notice and are experienced in all areas of standard-compliant heat and cooling water preparation.

according to VDI 2030

We clean - flush and fill your heating and cooling networks for a trouble-free operation of your plant

The standard-compliant cleaning, flushing and filling of heating and cooling networks must be thoroughly planned and professionally executed as otherwise malfunctions and cost risks can occur within a short time.

Our experienced employees support tradesmen in all work related to the standard-compliant cleaning, flushing and filling of heating and cooling networks.

Our teams can be deployed at short notice and are experienced in all areas of standard-compliant heat and cooling water preparation.

The advantages of working with us are obvious:

- Effective operations due to many years of experience

- Adherence to schedules and reliable planning

- Calculable costs

- Experience with problematic installations (corrosion damage etc.)

- All necessary equipment is at hand

- Many years of experience in all areas of water treatment and with the use of chemical inhibitors

- No guarantee risk

|

Standard-compliant raw material usage: avoid contamination to prevent high rehabilitation costs!

The HVAC system must be optimally prepared for filling. Dirt and impurities (foreign particles) are significant corrosion factors, which means that any introduction of impurities into the HVAC system must be avoided. Appropriate precautions must be taken as early as during the plant planning stage. Among other things, this is achieved by the use of clean and standard-compliant pipework materials (free of loose scale, rust, internal burrs and impurities), fittings and equipment (boilers, heat exchangers, radiators, convectors, expansion vessels, etc.) as well as by flawless production (with no weld beads, sealant or flux residues, burrs, swarf, etc.). It is necessary to clean all components of a heating system thoroughly prior to installation. |

Drinking water damages your heating and cooling systems! Do not let it come to that!

Safety by Alpenlandwater. Filling water processed in compliance with the VDI 2035 standard:

Our trained staff will be happy to advise you on how to reduce or prevent the formation of new deposits in heat exchangers!

Safety by Alpenlandwater. Filling water processed in compliance with the VDI 2035 standard:

- Softening

- Desalination

- pH-Stabilisation

- Reduced oxygen

- Chemical corrosion prevention

Our trained staff will be happy to advise you on how to reduce or prevent the formation of new deposits in heat exchangers!

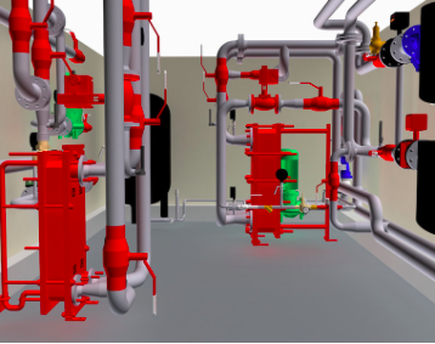

The Process

Refilling |

Problematic plant rehabilitation |

|

|

Prevention saves costs!

Especially the latest and most efficient technology has to be handled in the best possible way!