|

Fundamentals of Filling Water Treatment

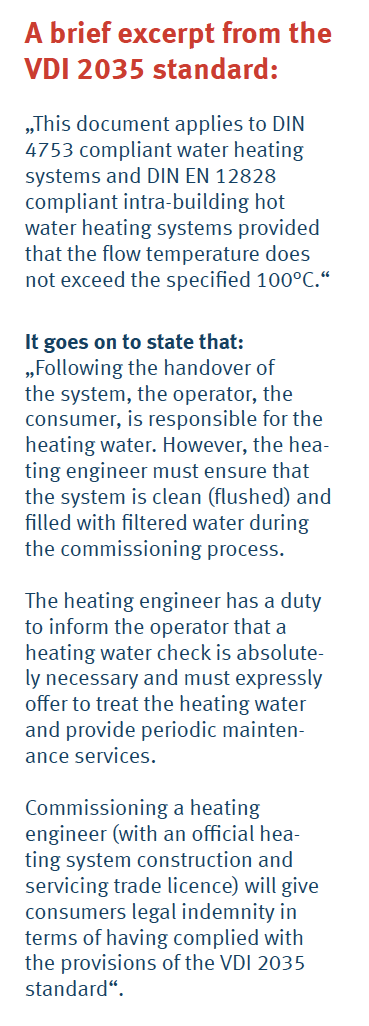

for heating and cooling networks according to VDI 2035 for a trouble-free operation of your cooling and heating network Why does water have to be treated for heating systems? More and more manufacturers of heating systems and components demand that the filling water is treated in accordance with VDI 2035 standard or with other similar specifications in the field of heating and cooling networks. If the filling water is not treated according to the manufacturer specifications, the filling of the heating or cooling system can become a warranty risk for the HVAC specialist or other responsible parties. The biggest problems in heating systems are caused by:

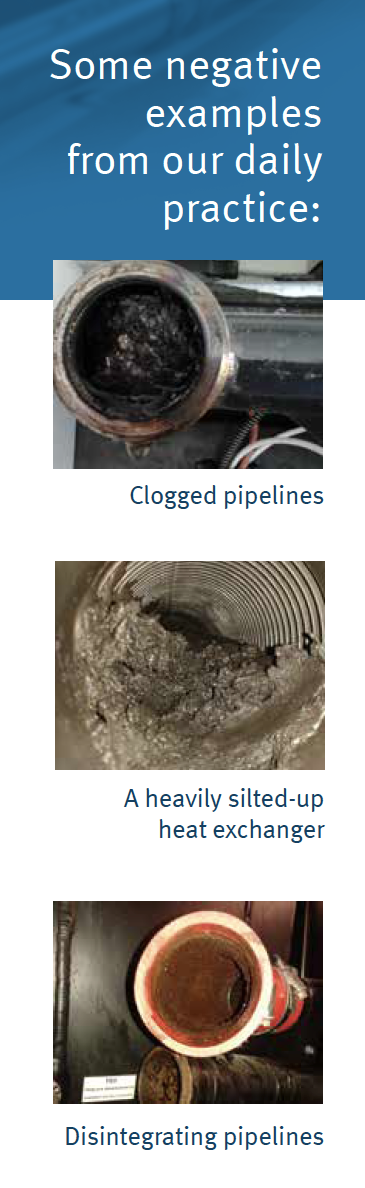

The consequences of improper water treatment:

This can be avoided! Alpenlandwater offers you the right water for all applications! |

Processes for filling water according to the VDI guidelines should include the following measures:

The theory is simple, but in practice it becomes too complicated for many planners, HVAC specalists and operators. Different manufacturers recommend different modes of operation in the preparation process. Is softened water fine or should rather demineralised water be used? Which chemical additives are required additionally? What must be done if the system is already contaminated with corrosion and sludge? The HVAC specalist or operator currently needs to buy the equipment and the chemicals separately and then do everything himself. If he makes mistakes, he is liable.

The company Alpenlandwater wants to go one step further:

With us the skilled HVAC specalist or operator receives all necessary standard-compliant materials. This is combined with a fair price and professional guidance. After all, the most important thing is the guidance of those responsible for the implementation. The current market leaders are to 90% active in the field of tap water and do not have the competence in heating water treatment to the level of detail the implementing HVAC specalist needs.

The focus of Alpenlandwater's is exactly here. And this will be proven in practice. In addition, we also supply the prepared heating water for filling on site. The filling water is prepared by us in accordance with standards and delivered directly to the destination address. The HVAC specialist can concentrate on his regular services and is no longer liable.

- Softening

- Desalination

- pH-Stabilisation

- Reduced oxygen

- Chemical corrosion prevention

The theory is simple, but in practice it becomes too complicated for many planners, HVAC specalists and operators. Different manufacturers recommend different modes of operation in the preparation process. Is softened water fine or should rather demineralised water be used? Which chemical additives are required additionally? What must be done if the system is already contaminated with corrosion and sludge? The HVAC specalist or operator currently needs to buy the equipment and the chemicals separately and then do everything himself. If he makes mistakes, he is liable.

The company Alpenlandwater wants to go one step further:

With us the skilled HVAC specalist or operator receives all necessary standard-compliant materials. This is combined with a fair price and professional guidance. After all, the most important thing is the guidance of those responsible for the implementation. The current market leaders are to 90% active in the field of tap water and do not have the competence in heating water treatment to the level of detail the implementing HVAC specalist needs.

The focus of Alpenlandwater's is exactly here. And this will be proven in practice. In addition, we also supply the prepared heating water for filling on site. The filling water is prepared by us in accordance with standards and delivered directly to the destination address. The HVAC specialist can concentrate on his regular services and is no longer liable.

Why can heating systems no longer be filled with drinking water?

In the past, heating pipes were made out of one material. Today pipes are made out of a mix of materials. Today, water comes into contact with a wide variety of materials, which can cause chemical reactions. Therefore, the heating water must have the properties of standard-compliant heating water in order to prevent damage to the system.

Pipe material today is also much smaller in diameter with thinner and lighter materials. They also no longer consist of a single piece, but are held together by connectors. This results in higher flow rate and the current becomes more turbulent. This results in increased abrasion of the materials.

Today's technological advances in your system, such as built-in sensors, probes, etc. require a higher water quality for smooth operation. Even small deposits and rust particles in the systems can lead to the failure.

That's why manufacturers demand certain qualities for filling their systems. But deionised water usually does not meet these requirements. In the event of damage caused by incorrect water quality, the manufacturer is no longer liable and you are left with the damages!

In the past, heating pipes were made out of one material. Today pipes are made out of a mix of materials. Today, water comes into contact with a wide variety of materials, which can cause chemical reactions. Therefore, the heating water must have the properties of standard-compliant heating water in order to prevent damage to the system.

Pipe material today is also much smaller in diameter with thinner and lighter materials. They also no longer consist of a single piece, but are held together by connectors. This results in higher flow rate and the current becomes more turbulent. This results in increased abrasion of the materials.

Today's technological advances in your system, such as built-in sensors, probes, etc. require a higher water quality for smooth operation. Even small deposits and rust particles in the systems can lead to the failure.

That's why manufacturers demand certain qualities for filling their systems. But deionised water usually does not meet these requirements. In the event of damage caused by incorrect water quality, the manufacturer is no longer liable and you are left with the damages!

Prevention saves costs!

Especially the latest and most efficient technology has to be handled in the best possible way!

|

Standard-compliant raw material usage: avoid contamination to prevent high rehabilitation costs!

The HVAC system must be optimally prepared for filling. Dirt and impurities (foreign particles) are significant corrosion factors, which means that any introduction of impurities into the HVAC system must be avoided. Appropriate precautions must be taken as early as during the plant planning stage. Among other things, this is achieved by the use of clean and standard-compliant pipework materials (free of loose scale, rust, internal burrs and impurities), fittings and equipment (boilers, heat exchangers, radiators, convectors, expansion vessels, etc.) as well as by flawless production (with no weld beads, sealant or flux residues, burrs, swarf, etc.). It is necessary to clean all components of a heating system thoroughly prior to installation. |

Drinking water damages your heating and cooling systems! Do not let it come to that!

Alpenlandwater Ltd.

2nd Floor.33 Cavendish sq - London W1G OPW

Mobile: 07388 845546

Phone: 020 7150 0789

Mobile: 07388 845546

Phone: 020 7150 0789