Prevention saves costs!

Especially the latest and most efficient technology has to be handled in the best possible way!

|

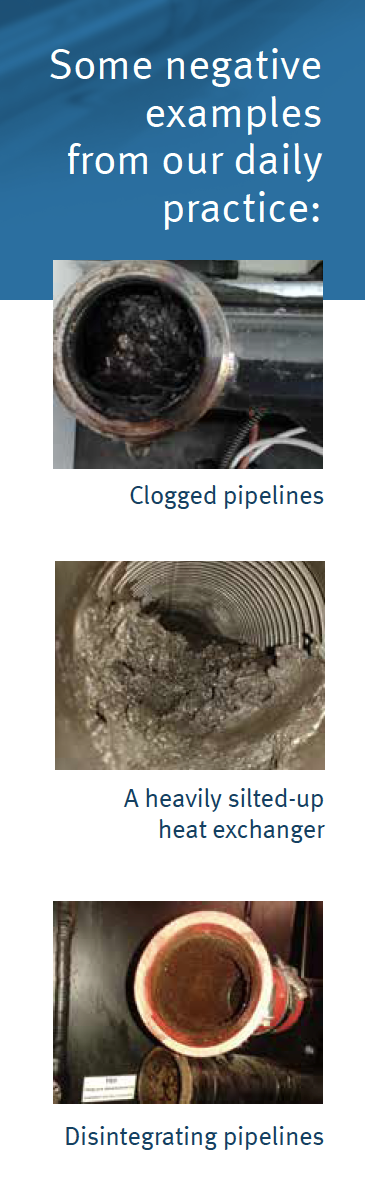

Standard-compliant raw material usage: avoid contamination to prevent high rehabilitation costs!

The HVAC system must be optimally prepared for filling. Dirt and impurities (foreign particles) are significant corrosion factors, which means that any introduction of impurities into the HVAC system must be avoided. Appropriate precautions must be taken as early as during the plant planning stage. Among other things, this is achieved by the use of clean and standard-compliant pipework materials (free of loose scale, rust, internal burrs and impurities), fittings and equipment (boilers, heat exchangers, radiators, convectors, expansion vessels, etc.) as well as by flawless production (with no weld beads, sealant or flux residues, burrs, swarf, etc.). It is necessary to clean all components of a heating system thoroughly prior to installation. |

Drinking water damages your heating and cooling systems! Do not let it come to that!